CONTINUOUS IMPROVEMENT

Continuous improvement revolves around machinery, employees, processes and suppliers. Collison-Goll is committed to improvement in all of these areas.

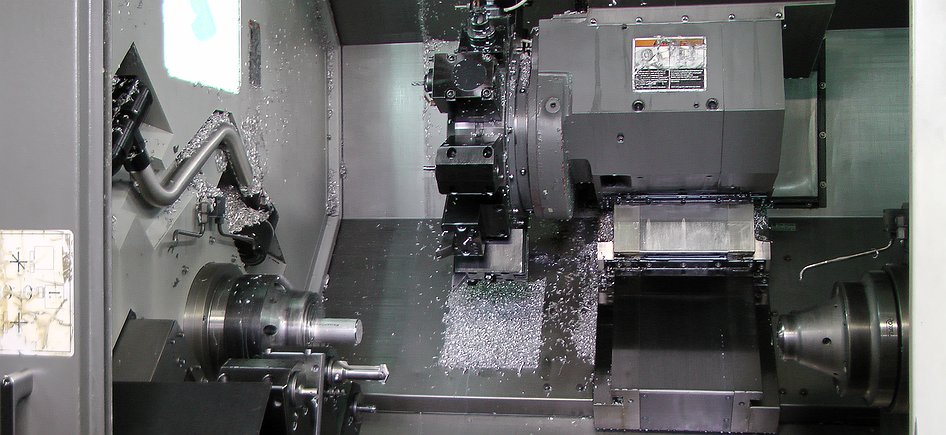

MACHINERY

Collison-Goll ensures its machinery will allow for continuous improvements by:

- Purchasing new equipment each year and replacing older equipment

- Using a computerized program for on-going maintenance and purchasing top quality replacement parts

- Consulting with top tier tool suppliers and using the most innovative tooling solutions.

EMPLOYEES

Collison-Goll employees are trained using the most current tools. Employees are constantly being trained on new machines which fosters new ideas and leads to improvements in quality and process flow.

PROCESSES

The process flow of all parts are constantly being reviewed. From the initial quote to the final delivery, each step is analysis with a view of improving quality or reducing costs by improving flow rates. A process flow chart is prepared for each part and improvements are often made with the addition of a new machine (reducing the number of operations), new ideas from the floor, or new tools, coatings or oil additives.

SUPPLIERS

Collison-Goll will only use suppliers that share our desire to continually improve and are ISO certified. This includes machinery and tool distributors, outside service providers, oil and coolant companies and firms providing employee services.