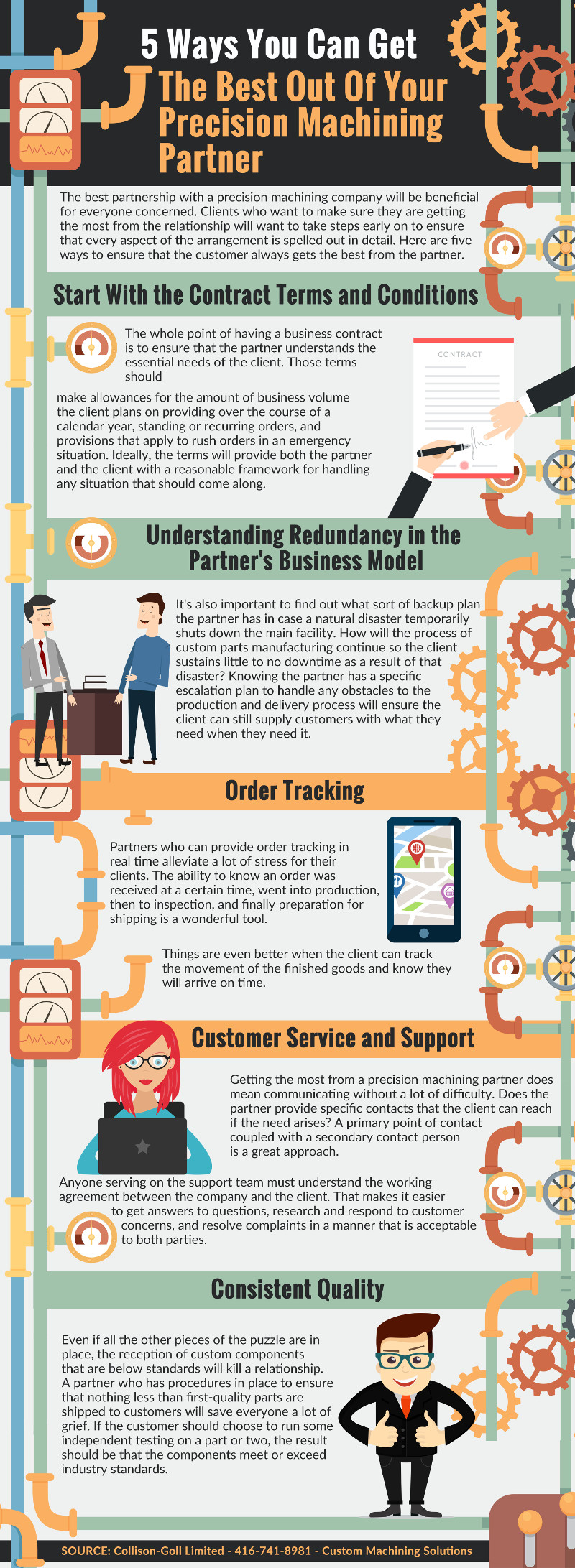

Custom Parts Manufacturing 101: 5 Ways You Can Get the Best Out of Your Precision Machining Partner

The best partnership with a precision machining company will be beneficial for everyone concerned. Clients who want to make sure they are getting the most from the relationship will want to take steps early on to ensure that every aspect of the arrangement is spelled out in detail. Here are five ways to ensure that the customer always gets the best from the partner.

Start With the Contract Terms and Conditions

The whole point of having a business contract is to ensure that the partner understands the essential needs of the client. Those terms should make allowances for the amount of business volume the client plans on providing over the course of a calendar year, standing or recurring orders, and provisions that apply to rush orders in an emergency situation. Ideally, the terms will provide both the partner and the client with a reasonable framework for handling any situation that should come along.

For example, what will happen if the client needs to increase the standing order for a particular component by 20%? How will that impact production schedules, delivery times, and the cost per unit? The right type of contract will cover this possibility and a lot more.

Understanding Redundancy in the Partner's Business Model

It's also important to find out what sort of backup plan the partner has in case a natural disaster temporarily shuts down the main facility. How will the process of custom parts manufacturing continue so the client sustains little to no downtime as a result of that disaster? Knowing the partner has a specific escalation plan to handle any obstacles to the production and delivery process will ensure the client can still supply customers with what they need when they need it.

Order Tracking

Partners who can provide order tracking in real time alleviate a lot of stress for their clients. The ability to know an order was received at a certain time, went into production, then to inspection, and finally preparation for shipping is a wonderful tool. Things are even better when the client can track the movement of the finished goods and know they will arrive on time.

Customer Service and Support

Getting the most from a precision machining partner does mean communicating without a lot of difficulty. Does the partner provide specific contacts that the client can reach if the need arises? A primary point of contact coupled with a secondary contact person is a great approach.

Anyone serving on the support team must understand the working agreement between the company and the client. That makes it easier to get answers to questions, research and respond to customer concerns, and resolve complaints in a manner that is acceptable to both parties.

Consistent Quality

Even if all the other pieces of the puzzle are in place, the reception of custom components that are below standards will kill a relationship. A partner who has procedures in place to ensure that nothing less than first-quality parts are shipped to customers will save everyone a lot of grief. If the customer should choose to run some independent testing on a part or two, the result should be that the components meet or exceed industry standards.

The right partner will always provide support and finished goods that make operations easier for the client. Unless those resources are in place, the best thing the client can do is search for another partner who will provide the level of service and support required.